Structural Materials

Establishing processing-structure-property (P-S-P) linkages is the most important part of alloy design. Conventional methods to establish P-S-P linkages such as experiments and simulations are resource intensive. However, these methods generate data which can be used extract the P-S-P linkages with machine learning (ML) techniques.

Simplifying the design strategy using machine learning for aerospace alloys, specifically nickel based superalloys and titanium alloys has been the prime focus of ThSim group. Large databases consisting of thousands of experimental data on Ni-based superalloys and titanium alloys have been developed. The data consists of microstructures, composition, and processing conditions of the alloys along with their mechanical and oxidation properties such as yield strength, hardness, creep, fatigue life, mass gain and rate of oxidation.

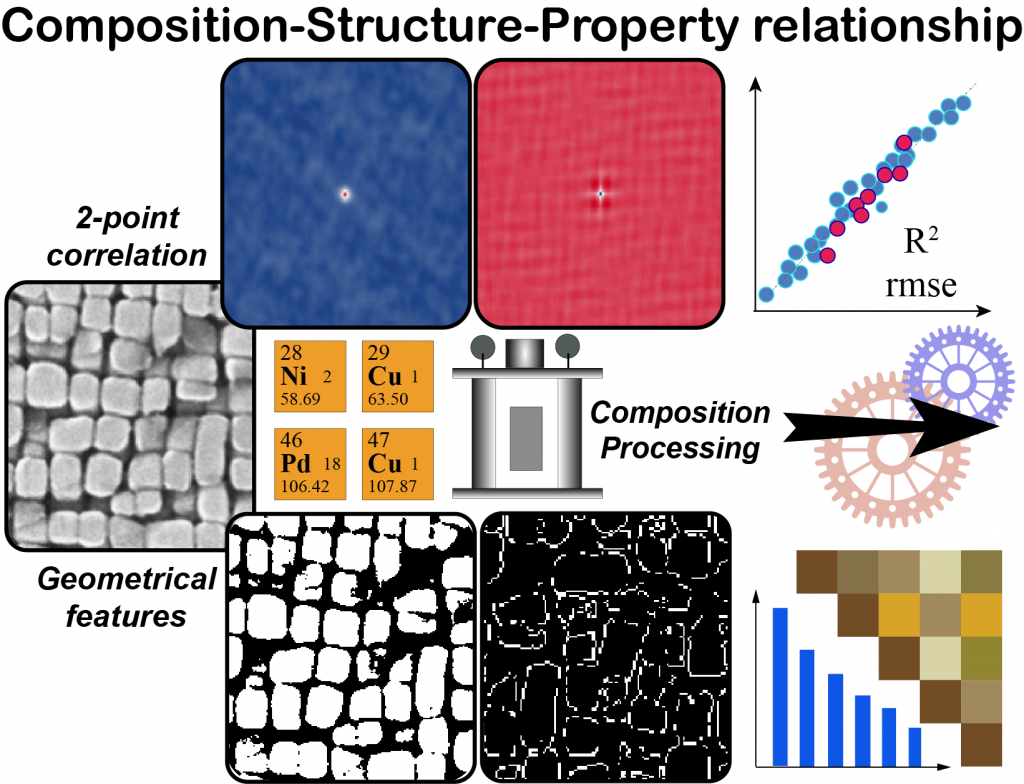

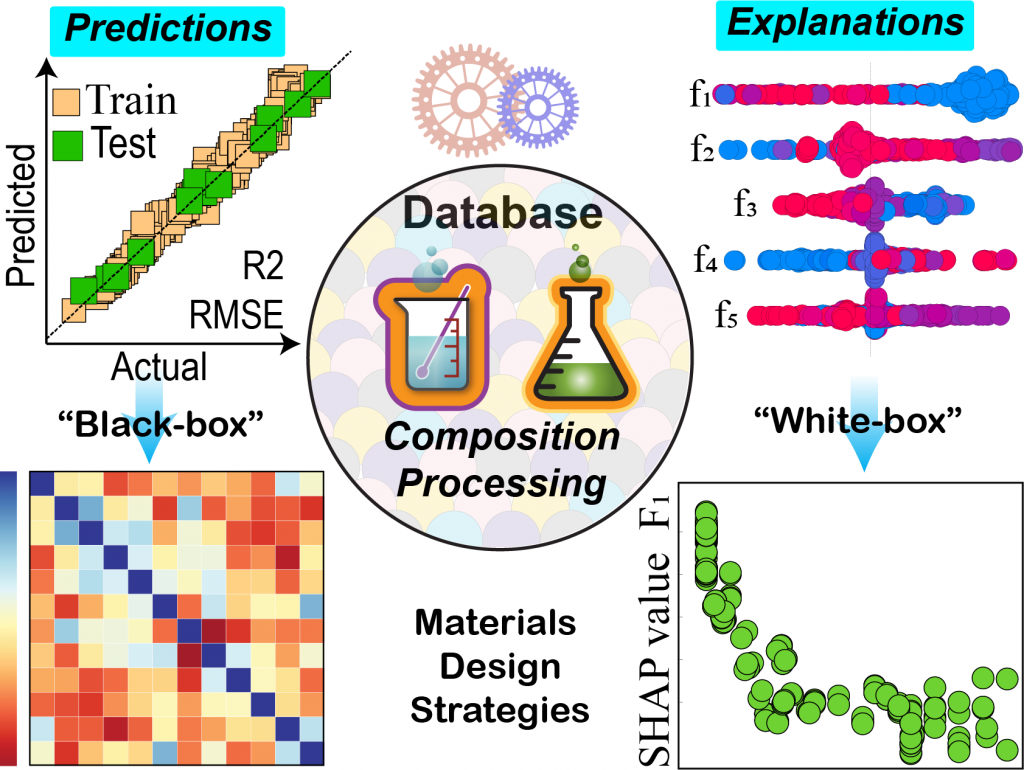

The microstructural data was used to establish structure-property linkages in Ni-based superalloys using a combined framework of image processing and machine learning tools for prediction of Vickers hardness [1,2]. Highly interpretable machine learning models were constructed to predict yield strength, ultimate tensile strength, creep rupture life, fatigue life in Ni-based superalloys and creep rupture life and fatigue life in Titanium alloys [3,4]. These models were extensively used to study effects of alloying elements and processing conditions on the mechanical properties and further make recommendations to optimize these parameters. Extensive work is also being performed on corrosion properties of Ni-based superalloys.

First principles calculations were used to augment machine learning predictions and draw out explanations for various physical phenomena. Effect of alloying elements on stacking faults have been extensively studied in superalloys.

Reference

- 1. Khatavkar, N.; Swetlana, S.; Singh, A. K. Accelerated Prediction of Vickers Hardness of Co- and Ni-Based Superalloys from Microstructure and Composition Using Advanced Image Processing Techniques and Machine Learning, Acta Mater., 196, 295-303, (2020)

- 2. S. Swetlana, N. Khatavkar, and A. K. Singh, Development of Vickers hardness prediction models via microstructural analysis and machine learning, J. Mater. Sci., 55, 15845–15856, (2020)

- 3. N. Khatavkar, and A. K. Singh, Highly interpretable machine learning framework for prediction of mechanical properties of nickel based superalloys, Phys. Rev. Materials, 6, 123603 (2022)

- 4. S. Swetlana, A. Rout, A. K. Singh, Machine Learning Assisted Interpretation of Creep and Fatigue Life in Titanium Alloys, APL Machine Learning, 1, 016102 (2023)